Key Elements Of A Minimalist Bedroom Setup For Tranquility

Key elements of a minimalist bedroom setup pave the way for a harmonious living space that embodies tranquility and simplicity. By stripping away the unnecessary, this style focuses on creating an environment that promotes relaxation and mental clarity. Imagine a room where each piece of furniture serves a purpose, where color palettes are soothing, and where the air is filled with serene energy, allowing you to unwind effortlessly.

The essence of minimalist design lies in its commitment to simplicity and functionality. Essential features include multifunctional furniture and a carefully curated color scheme, which together foster an inviting atmosphere. By embracing neutral tones and natural materials, you can craft a sanctuary that not only looks beautiful but also feels peaceful and uncluttered.

Essential Features of a Minimalist Bedroom

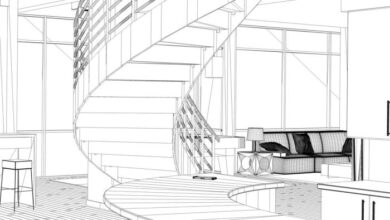

A minimalist bedroom embraces the philosophy of simplicity, creating a serene environment that enhances relaxation and clarity. By focusing on the essential elements, this design approach facilitates a sanctuary that promotes peace and order, allowing individuals to unwind and recharge effectively.Central to minimalist design is the use of furniture that adheres to clean lines and functional forms. This furniture not only serves a purpose but also contributes to an uncluttered aesthetic.

The choice of furnishings impacts the overall feel of the space, making it crucial to select pieces that embody the principles of minimalism.

Furniture Types that Promote Minimalism

In a minimalist bedroom, the selection of furniture plays a vital role in achieving the intended aesthetic. The following types of furniture are particularly effective in promoting a minimalist environment:

- Platform Beds: These low-profile beds create a streamlined look and eliminate the need for bulky frames, emphasizing simplicity.

- Nightstands: Opt for small, unobtrusive designs that provide functionality without overpowering the space.

- Multi-Functional Furniture: Pieces such as storage benches or ottomans serve dual purposes, reducing the need for excess items.

- Simple Desks: A sleek writing desk can enhance productivity while maintaining an uncluttered appearance.

- Minimalist Wardrobes: Wardrobes with clean lines and simple handles promote a streamlined look while offering ample storage.

Each piece should harmonize with the overall design theme, ensuring that the bedroom remains an oasis of calm.

Color Palettes for a Serene Environment

The choice of colors significantly influences the mood and atmosphere of a minimalist bedroom. A well-considered color palette can evoke tranquility and promote relaxation, essential for a restful space. Neutral tones are often preferred in minimalist design, as they create a sense of openness and balance. Consider the following elements when selecting colors:

- Soft Whites and Creams: These colors enhance natural light and create an airy feel, making the space appear larger and more inviting.

- Muted Grays: Gray tones provide a sophisticated backdrop that complements various accent colors without overwhelming the senses.

- Earthy Hues: Shades like taupe, beige, and soft greens connect the indoor environment with nature, fostering a sense of grounding.

- Accent Colors: Consider adding a single accent color through decor items like cushions or wall art, ensuring it aligns with the overall calming theme.

By carefully selecting a cohesive color scheme, a minimalist bedroom can maintain its serene atmosphere while reflecting personal style.

To enhance the air quality in your bedroom, consider incorporating some greenery. Certain plants not only beautify your space but also purify the air. For example, the best plants for improving bedroom air quality include varieties like snake plants and peace lilies, which effectively filter toxins and release oxygen, creating a healthier sleeping environment.

“The essence of minimalism lies in its ability to amplify tranquility through simplicity.”

Furniture Selection for Minimalist Bedrooms

Creating a minimalist bedroom demands careful consideration of furniture choices. The goal is to cultivate a serene and uncluttered environment that promotes relaxation and simplicity. This can be achieved by selecting furniture that embodies functionality, aesthetic appeal, and space efficiency.A crucial aspect of furniture selection in a minimalist bedroom is the incorporation of multifunctional pieces. This approach not only conserves space but also enhances the room’s versatility.

Choosing items that serve multiple purposes can significantly reduce visual clutter and contribute to a harmonious atmosphere.

Multifunctional Furniture Guidelines

Opting for multifunctional furniture can transform a minimalist bedroom into a practical and stylish haven. When selecting such furniture, consider the following guidelines:

- Storage Solutions: Look for beds with built-in drawers or ottomans that can store extra bedding. This maximizes storage while minimizing the need for additional furniture.

- Convertible Pieces: Choose items like sofa beds or folding desks that can adapt to varying needs, allowing for easy transitions between sleeping and working.

- Nesting Tables: Incorporate nesting tables that can be easily moved or tucked away to free up space when not in use, providing flexibility in layout.

- Wall-Mounted Options: Consider wall-mounted desks or shelves that save floor space while providing necessary functional areas for work or display.

Balancing size and scale is equally vital when selecting furniture for a minimalist bedroom. Appropriate sizing ensures that each piece complements the available space, enhancing the room’s overall aesthetic.

Size and Scale Considerations

Selecting the right size and scale of furniture is essential to maintain the airy and open feel characteristic of minimalist design. Here are key considerations to keep in mind:

- Proportionality: Ensure that each piece of furniture is proportionate to the room’s dimensions. Oversized items can overwhelm a small space, while tiny pieces may look lost in a larger room.

- Visual Weight: Choose furniture with a lighter visual weight, such as legs that elevate pieces off the ground, creating a sense of openness.

- Negative Space: Maintain ample negative space around furniture to enhance the minimalist concept; this allows for better movement and reduces a cramped feeling.

Finally, the emphasis on quality over quantity is paramount in choosing furniture for minimalist bedrooms. Investing in fewer, high-quality items can lead to a more satisfying and enduring aesthetic.

Importance of Quality in Furniture Choices

Prioritizing quality over quantity not only supports a minimalist ethos but also contributes to long-term satisfaction with your space. Here are reasons why quality furniture is significant:

- Durability: High-quality materials ensure that furniture withstands daily use, reducing the need for replacements and promoting sustainability.

- Timeless Appeal: Well-crafted pieces often exhibit timeless designs that transcend trends, making them relevant for years to come.

- Enhanced Comfort: Investing in quality furniture translates to improved comfort, which is essential for a restful bedroom environment.

- Clear Aesthetics: Quality items typically feature clean lines and thoughtful design, aligning with the minimalist aesthetic of simplicity and refinement.

By focusing on multifunctional furniture, appropriate size, and high-quality selections, one can create a minimalist bedroom that is both practical and visually pleasing.

Color Schemes and Textures

The choice of colors and textures in a minimalist bedroom is pivotal in creating a serene and harmonious environment. By utilizing a restrained palette and carefully selected materials, you can enhance the overall ambiance of the space, promoting relaxation and tranquility. This approach not only helps maintain a clutter-free aesthetic but also elevates the emotional quality of your personal retreat.Neutral colors serve as a foundation for a minimalist bedroom, influencing the environment’s mood and fostering a sense of peace.

Shades such as whites, beiges, and soft grays can create a calming backdrop that enhances natural light, making the space feel larger and more open. These colors allow for versatility and compatibility with various decor elements, ensuring that the bedroom remains visually cohesive without overwhelming the senses.

Impact of Neutral Colors on Bedroom Ambiance

Neutral colors contribute significantly to the overall vibe of a minimalist space. They evoke feelings of comfort and clarity, creating a sanctuary that promotes restfulness. Consider the following aspects when integrating neutral colors into your bedroom:

- Light Reflection: Neutral tones reflect light effectively, making small spaces appear more expansive and airy.

- Emotional Calm: Colors like soft beige or muted gray can reduce stress and anxiety, fostering a tranquil atmosphere.

- Timelessness: Neutral palettes are enduring, allowing for easy adaptation and evolution of the space’s design over time.

The addition of textures can further enhance the minimalist aesthetic, adding depth and interest without introducing clutter. Textural variety can make a space feel layered and inviting while adhering to the principles of minimalism.

Use of Textures to Add Depth

Incorporating different textures allows for a dynamic yet understated design. By combining various materials, you can create visual intrigue that captivates the eye without overwhelming the space. Here are some effective ways to introduce texture into a minimalist bedroom:

- Textured Fabrics: Utilize bedding, throw pillows, or curtains made from linen, wool, or cotton to introduce warmth and comfort.

- Natural Elements: Incorporate wooden furniture or accents to add organic texture, promoting a sense of connection with nature.

- Layered Rugs: Opt for a combination of rugs—perhaps a plush area rug atop a flat-weave—for added tactile richness while maintaining minimalism.

Natural materials are essential in a minimalist design, as they not only enhance aesthetic appeal but also contribute to sustainability. Incorporating elements like wood, stone, and plants can create a serene and balanced environment.

Incorporation of Natural Materials

Natural materials harmonize beautifully with minimalist design by fostering a sense of authenticity and grounding. They resonate with eco-friendly principles while adding visual warmth. Implement these materials in your bedroom as follows:

- Wood Furniture: Choose pieces made from reclaimed or sustainably sourced wood to emphasize natural beauty and craftsmanship.

- Stone Accents: Introduce stone elements through decor items or wall features to add an earthy touch that contrasts gently with softer textures.

- Living Plants: Incorporate greenery through potted plants or a small indoor garden to breathe life into the space and improve air quality.

By thoughtfully selecting color schemes and textures, along with the careful integration of natural materials, you can cultivate a minimalist bedroom that exudes tranquility and sophistication.

Storage Solutions in Minimalism

In a minimalist bedroom, effective storage solutions are crucial for maintaining a zen-like environment. By integrating innovative storage ideas, you can keep your space organized and visually appealing, ensuring that every item has its place without cluttering the atmosphere. This guide explores various approaches to achieving an uncluttered space while seamlessly blending functionality with aesthetics.

Innovative Storage Ideas

Finding storage solutions that align with minimalist principles requires creativity. Here are some innovative ideas that can maintain a clean look while providing ample space for your belongings:

- Under-bed Storage: Utilize the space beneath your bed with flat storage boxes or drawers. This area is often overlooked, yet it’s perfect for storing seasonal clothing or extra linens, keeping them out of sight and organized.

- Multi-functional Furniture: Invest in furniture that serves dual purposes, such as a bench with storage inside or a coffee table that opens up for additional space. These pieces can declutter the room while providing essential functions.

- Wall-mounted Shelves: Install shelves above your bed or desk to create vertical storage that takes advantage of wall space. This not only provides storage but also allows for decorative displays that enhance the room’s aesthetic.

Decluttering and Organizing Methods

To maintain a minimalist bedroom, adopting effective decluttering methods is essential. Emphasizing simplicity, here are some practical strategies for organizing personal items:

- The One-In, One-Out Rule: For every new item brought into the space, an existing item should be removed. This helps control the accumulation of belongings and ensures a balanced environment.

- Regular Purging: Set aside time every few months to evaluate your possessions. Remove items that no longer serve a purpose or bring you joy, promoting a sense of clarity and space.

- Use Clear Storage Bins: Store similar items together in clear bins, labeled for easy identification. This method not only organizes but also allows you to see what you have at a glance, making it easier to maintain order.

Hidden Storage Options

Incorporating hidden storage solutions can dramatically enhance the minimalist aesthetic of your bedroom. These options blend seamlessly with your decor while providing essential storage capabilities:

- Built-in Wardrobes: Consider custom-built wardrobes that fit perfectly into alcoves or awkward spaces. These can be designed to include hidden compartments for shoes, accessories, and other items, maximizing your room’s potential without sacrificing style.

- Storage Ottomans: Choose decorative ottomans that open up for storage. These can serve as seating or footrests while discreetly hiding away blankets, books, or other essentials.

- Floating Nightstands: Install floating nightstands to create an illusion of more space underneath. These can be designed with drawers or shelves that provide hidden storage for nighttime necessities without taking up floor space.

Lighting Considerations

Natural light plays a crucial role in minimalist bedrooms, enhancing the spacious and serene atmosphere that this design style embodies. The key to achieving a tranquil environment lies in maximizing daylight while incorporating thoughtful artificial lighting that complements the overall aesthetic. By carefully selecting light fixtures and implementing various lighting techniques, you can create a harmonious blend of functional and ambient illumination.Choosing light fixtures that align with a minimalist style is essential for maintaining a cohesive look.

To enhance the air quality in your bedroom and promote better sleep, incorporating greenery can be a game-changer. Plants like the snake plant and peace lily are not only visually appealing but also among the best plants for improving bedroom air quality. These natural air purifiers help filter toxins, ensuring a refreshing atmosphere for restful nights.

Fixtures should be streamlined and unobtrusive, often featuring clean lines and a simple color palette. Opt for designs that not only serve a practical purpose but also contribute to the overall ambiance without overwhelming the space.

Natural Light Optimization

Taking advantage of natural light can transform the feel of a minimalist bedroom. Windows should be unobstructed by heavy drapes or elaborate window treatments to allow sunlight to filter in freely. This approach not only brightens the space but also creates a connection with the outdoors.

Utilize sheer curtains

These allow light to enter while providing a degree of privacy.

Strategically place mirrors

Mirrors can reflect natural light, amplifying its effect and making the room feel more expansive.

Choose light colors for walls

Soft, light colors will bounce light around the room, enhancing the sense of airiness.

Artificial Lighting Selection

When choosing artificial lighting, it’s vital to select fixtures that embody minimalist principles. Simple pendant lights, recessed lighting, and wall sconces are ideal choices.

Focus on functionality

Each light fixture should serve a purpose, providing adequate illumination for tasks such as reading or dressing.

Materials matter

Opt for materials like metal, glass, or wood that are both durable and visually appealing without being overly ornate.

Dimmer switches

Installing dimmers gives flexibility to adjust light levels, creating a soft glow during evening hours.

Layering Light Sources

Layering different types of lighting enhances the ambience of a minimalist bedroom. This technique involves combining ambient, task, and accent lighting to create a well-rounded and inviting atmosphere.

Ambient lighting

This is the primary source of illumination, typically from ceiling fixtures or natural light.

Task lighting

Incorporate bedside lamps or adjustable wall sconces for focused light during reading or other activities.

Accent lighting

Use spotlights or LED strips to highlight artwork or architectural features, adding depth and interest to the decor.By thoughtfully integrating these elements, you can establish a balanced lighting design that aligns with the minimalist philosophy while ensuring comfort and functionality. The interplay of natural and artificial light will not only enhance the aesthetic appeal but also promote a sense of calm and tranquility within the space.

Personal Touches in Minimalism

Incorporating personal touches into a minimalist bedroom setup can enhance the space while maintaining its clean and uncluttered aesthetic. The key to achieving this balance lies in selecting meaningful decor that reflects your personality without overwhelming the simplicity that defines minimalism. To successfully infuse personal items into your minimalist bedroom, it is essential to curate a selection that embodies your values and experiences, without adding unnecessary clutter.

Minimalism encourages individuals to focus on quality over quantity, ensuring that each item serves a purpose or brings joy.

Incorporating Personal Items without Clutter

When it comes to personalizing a minimalist space, consider the following strategies that enhance your decor without compromising the clean line aesthetic:

- Artful Display: Choose a single piece of art or a well-framed photograph that resonates with you. This can serve as a focal point in the room, amplifying your personal style while keeping the space open.

- Sentimental Objects: Select a few cherished items like a decorative box or a unique vase that holds memories. Limit these to one or two pieces to avoid overcrowding.

- Textiles with Meaning: Incorporate textiles such as a throw blanket or decorative pillows that reflect colors or patterns meaningful to you. Ensure they complement the overall color scheme to maintain coherence.

- Books that Inspire: A small collection of your favorite books can double as decor and intellectual stimulation. Choose a few that resonate with your interests and display them neatly on a minimalist shelf.

- Greenery: A single potted plant can bring life to your bedroom. Choose a low-maintenance variety that aligns with your lifestyle while adding a natural touch without clutter.

Balancing Minimalism and Personal Expression

Striking a balance between minimalism and personal expression is crucial for creating a comfortable environment. It involves careful consideration of what items truly represent you and how they fit within a minimalist framework.

“Minimalism is about more than just eliminating excess; it’s about making room for what truly matters.”

This philosophy guides the selection of decor, where each item should serve a dual purpose of aesthetic appeal and personal significance. The goal is to create a space that feels authentically yours while adhering to minimalist principles.

Selecting Decor that Aligns with Minimalist Principles

Choosing decor that aligns with minimalism involves several key considerations. These aspects ensure that your personal touches harmonize with the overall aesthetic of simplicity:

- Neutral Color Palette: Opt for neutral tones or monochromatic schemes that promote tranquility. Accent colors can be introduced sparingly through small decor items.

- Functional Design: Select pieces that are not only visually appealing but also functional. Multi-use furniture, like an ottoman that can serve as storage, is ideal.

- Quality over Quantity: Invest in fewer, high-quality items that will stand the test of time and continue to bring joy, rather than accumulating numerous low-quality pieces.

- Open Space: Maintain open areas within the room to enhance the feeling of spaciousness. This means that every piece should have its designated space without crowding.

- Natural Elements: Incorporating natural materials such as wood, stone, or organic textiles can add warmth and texture without overwhelming the simplicity of the design.

Creating a Relaxing Atmosphere: Key Elements Of A Minimalist Bedroom Setup

In the minimalist bedroom, the atmosphere plays a crucial role in achieving tranquility and comfort. By carefully considering scents, sounds, and the inclusion of natural elements, one can transform the space into a serene retreat that promotes relaxation and mindfulness. Here, we explore the essential components that contribute to a calming environment, making your minimalist bedroom not just a place to sleep, but a sanctuary for the mind and body.

Utilizing Scents and Sounds

Incorporating soothing scents and sounds into a minimalist bedroom greatly enhances the overall ambiance. Aromatherapy can significantly influence mood and relaxation, making the selection of scents vital. Essential oils such as lavender, chamomile, and sandalwood have been shown to reduce stress and promote a sense of calm. Utilizing a diffuser allows these scents to permeate the room gently. Sounds also play a pivotal role; subtle background noises can mask distractions.

Consider gentle instrumental music or nature sounds, like ocean waves or rustling leaves, which can create a serene soundscape. To effectively implement these sensory elements:

- Use a diffuser with calming essential oils to promote relaxation.

- Install a sound machine or play soft nature sounds to drown out disruptive noise.

- Create a playlist of tranquil music that can be streamed during your relaxation time.

The Role of Plants

Integrating plants into your minimalist bedroom setup not only adds an aesthetic appeal but also fosters a deeper connection to nature. Plants such as snake plants, peace lilies, and pothos are excellent choices due to their air-purifying qualities and low maintenance needs. Incorporating greenery has been shown to reduce anxiety, enhance mood, and improve overall well-being. The presence of plants creates a more inviting atmosphere and can help to soften the starkness often associated with minimalism.To create a tranquil environment with plants:

- Opt for low-maintenance plants that thrive in indoor conditions.

- Arrange plants in visually appealing spaces, such as on window sills or bedside tables.

- Consider hanging planters to maximize space while adding greenery.

Creating a Cozy Environment, Key elements of a minimalist bedroom setup

Despite the simplicity of a minimalist setup, it’s entirely possible to cultivate a cozy and inviting atmosphere. This can be achieved through the careful selection of textures and the strategic placement of furniture. Soft textiles, like linen or cotton throws, can create warmth without overwhelming the simplicity of the design.Lighting should also be considered; soft, warm lighting can help to create an intimate feel.

Incorporating additional layers of lighting, such as bedside lamps or dimmable overhead lights, allows for versatility in setting the desired mood.To enhance the coziness of your minimalist bedroom:

- Incorporate various textile layers, such as throws and cushions, in natural colors.

- Use warm lighting options to create a soothing glow in the evening.

- Position furniture to foster conversation and warmth, avoiding a sterile layout.

Ending Remarks

In summary, achieving the ideal minimalist bedroom setup involves thoughtful selection of furniture, an intentional color palette, and innovative storage solutions that enhance, rather than hinder, the overall aesthetic. By incorporating personal touches and focusing on creating a relaxing atmosphere, you can transform your bedroom into a calming retreat that reflects both minimalism and individuality. Ultimately, the journey to minimalism is not merely about reduction; it’s about enhancing your quality of life through mindful living.